Graham Cocksedge, now in his seventies, vividly remembers the moment as a teenager when his father, an aviation engineer and keen inventor, was inspired to create a vehicle that was more efficient over water than a boat. “We were at the marina one day, watching boats move through the water by pushing the water aside with their bows. My father said; ‘We must be able to do better than that.’”

Two weeks later, a prototype model appeared at their home in Ontario, Canada, using an engine from a model plane attached to a simple aluminium deck. Cocksedge remembers it well; “At first, the back end jumped up and it didn’t move. My dad got a brick from the barbecue, and rested it on the rear of the model, and it just took off across the grass! And that was the beginning.”

Prototypes evolved and grew, all with the fundamental principle of an energised column of air passing under the vessel, powered by a single fan motor which lifted the craft out of the water while also providing thrust. Vanes controlled speed, direction and lift. The scale of the models grew, to a 6 metre, VW-powered ride-on craft. Cocksedge, a student of mechanical engineering at the time, wrote up his father’s concept for his degree thesis, explaining and testing the concept.

And then life got in the way. Cocksedge became an engineer, and his brother, Bill, became a public health expert. But in retirement, their thoughts returned to the potential of their father’s invention. In the last few years, they’ve created a company – Slipstream – and enlisted the help of marine technical and commercial advisers, Tynebridge Solutions Inc, who also believe the Thrust Cushion Vehicle, or TCV, has real potential in a maritime sector looking for increased transport efficiency.

Efficiency gains

The brothers say the TCV has some valuable advantages over traditional vessels. The first is speed; they say over 60 knots in the right sea conditions. In the water surrounding their home, saturated logs sitting just below the water are a common problem – disastrous for conventional craft, or even hydrofoils, travelling at speed, but a TCV would glide over.

So far, so hovercraft. But the TCV has advantages over its air-cushioned cousin, say designers. Hovercraft need to provide thrust in two directions; down, to raise them out of the water, and horizontally, to provide motion. A TCV needs just one thrust direction, directing air beneath the boat from the front.

The TCV team say that means less power is required, with significant fuel economy savings – up to 50% over a similar sized conventional vessel. Their assumptions are based on a 32 metre, turbine-electric TCV carrying 200 people over a distance of 14 nautical miles, compared to a foil-assisted catamaran design. At a 50% passenger load rate, and taking into account the doubling of cruise speed, they say the TCV would offer a fuel cost of $0.60 per passenger, compared to $2.71 for the catamaran. They say fully electric TCVs could offer even greater benefits.

“All of the physics are right”, says Bill Cocksedge. ‘’The energy needed for lift is retained for thrust, with air flowing parallel to the direction of motion. Comparatively light pressures are needed – around 0.25psi.”

Another advantage to consider is reduced running costs, say Slipstream. A TCV has no ‘skirts’; the flexible cowling on a hovercraft which maintains a cushion of air, which needs replacing over time. Instead, a TCV’s fixed hulls do a similar job.

Like a hovercraft, there’s low underwater noise and low wash, albeit with superior course-keeping and manoeuvring characteristics, using the lateral grip from the hulls. It’s a factor becoming increasingly important environmentally, especially in wilderness areas where a TCV can travel over water and land with equal ability. Another feature is its low freeboard and stability at rest on the water – perfect for search and rescue vessels along coasts.

The development valley

As many inventors can testify, a great concept does not always translate into instant commercial success. The Slipstream TCV has never been developed commercially. A small prototype exists, but what’s needed is a full-scale, working test vessel to literally “get the project off the ground (excuse the pun)” says Robert Hedley, President of Tynebridge Solutions. His estimate is an investment of between $5-$10 million for a 20-metre demonstrator craft, depending on detailed engineering costs, which he says would bridge the valley between engineering concept and commercial orders.

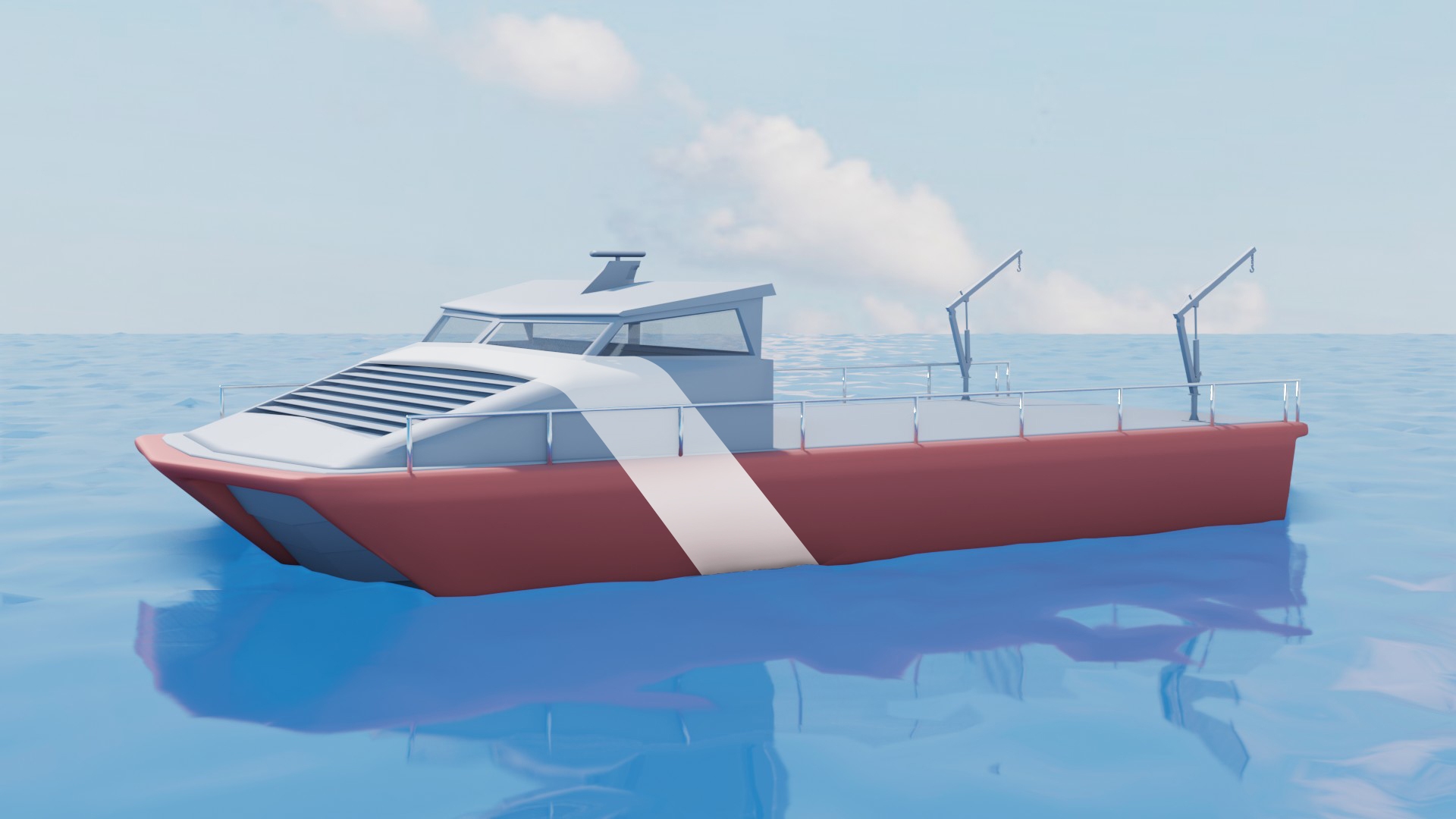

Various lengths of craft – from 6m to 120m - have been considered for different applications of a high-speed amphibious TCV, including a passenger ferry, a search and rescue craft, firefighting, oil spill response, icebreaker evacuation craft, medical evacuation, various military applications, eco-tourism or as a yacht tender.

“We’ve spoken to Canadian Coastguard”, says Hedley, “and search and rescue seems like a perfect application. A TCV is fuel agnostic – a battery or fuel cell would work, making a zero-emission vessel is feasible.”

The Cocksedge brothers hope the fuel flexibility, economy and all-terrain practicality of the TCV means a dedicated innovator can bring their father’s idea to life. As Bill Cocksedge puts it, “After all these years, the solution is still elegant engineering.”